| Vegetable oil based road fuels for diesel engines. |

| Vegetable oils can be used in diesel engines either in it's neat form, called straight vegetable oil (SVO), or in forms produced as a result of chemical reactions such as transesterification. There are a number of different recipes for producing shorter chain length chemical structures and these products are called bio-diesel or E-diesel or similar. There are many arguments for using each of these fuels in preference to the other and the following page argues in favor of SVO: http://www.goatindustries.fsnet.co.uk/svoreport.htm |

| Prototype bio-diesel plant photographs. |

|

|

| The photograph above shows a prototype bio-fuel production plant composed of, from right to left, a stainless steel methoxide mixer, a pump, a fuels mixer with internal paddle and a settlement/bubble-wash tank. In the transesterification reaction, methanol is firstly mixed with a small amount of caustic soda and then pumped into the fuel mixing tank where it is mixed with vegetable oil at approx. 55 degrees C. After about 2 hours the reactants are pumped into the tank with the conical bottom and one of the products, glycerin, is allowed to settle out to the bottom. The glycerin is drawn off from the bottom and the remaining liquid is washed by adding water and bubbling air from the bottom. One of the main problems with this process is 'what do you do with the dirty water?' It can be treated with acid to neutralize the Ph but there are still large amounts of water to be disposed of. | |

|

The photo above shows methyl ester, or 'bio-diesel' and glycerin produced from the transesterification of waste vegetable oil that can be collected from pubs and hotels. The sample shows two distinct layers, the glycerin and the methyl esters. To get clean, clear diesel the top layer must be washed with water by a process called bubble washing. |

|

|

The photo on the left shows the top of the fuels mixer. The flywheel seen is powered by a domestic washing machine motor which itself drives a shaft mounted on two bearing blocks with a paddle on the end. A gas burner is used to pre-heat the oil. There are many safety issues to be aware of when producing fuel in this way. Methanol is extremely inflammable and methoxide extremely corrosive. Fire or explosions could be caused by sparks from the motor, static electricity from mixing methanol and localized pressure development in the pump. |

| Vegetable oil processing trailer |

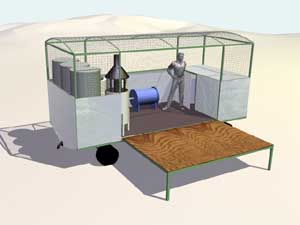

| Goat industries is involved in the production and promotion of vegetable oil based fuels and our equipment is operated within the specially built trailer shown below and on the right. One of the main problems with dealing with vegetable oils was that it produced a lot of mess on the floor very quickly. The oil spills out of pipe connections every time they are undone and then spreads over the floor from being trodden in, producing a dangerous, slippery surface. We solved this problem by using an industrial type metal grid flooring set in five panels on large galvanized iron drip trays. The trays each have four drain holes with pipes attached below to collect oil and water. |

The other side of the trailer, as seen above, is mostly open and makes it appropriate for demonstration purposes at agricultural shows etc. |

|

|

|

Waste vegetable oil filtration |

|

|

| The photo below shows filtration equipment for producing SVO ready for the road. Waste oil from pubs and hotels can be heated in the blue oil drum to about 40 degrees C and then pumped into the conical filter on top of the green drum. 200 liters of oil may need a couple of clean filters to hand. They can be easily changed when clogged up and are held in place by the cord tied over the rim of the drum. The filtered oil can then be stored in smaller containers with sealable lids to keep air out. Oil can be stored for a long time in this way. |